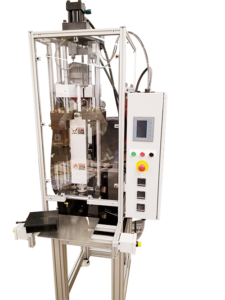

Many injection molded parts do not require a high volume (greater than 100,000 parts per year) injection molding machine. Higher production machines are expensive, require considerable floor space, and require expensive multi-cavity hard steel tooling. MPM machines are optimized for lower volume plastic molded parts. They are cost effective, require a small footprint, and can use single cavity low cost tooling. Low Volume injection molding machines are a good fit for smaller production orders, prototyping, bridge manufacturing, and ASTM specimen applications.

Low Volume Injection Molding Machines

Smaller Production Injection Molding

If you need to produce parts in smaller production batches, you should consider low volume injection molding (LVIM) machines:

LVIM machines are cost effective

Small footprint - can be a benchtop or compact floor standing configuration

Easy set up and changeover with recipe capability

Low cost easy to produce single cavity tooling with insert cavity capability

See What Mini Injection Molding Can Do For Your Business

Get the ultimate guide to low volume plastic injection molding

Prototyping and First Production Articles

Going from a product design to full production can be costly, time consuming, and cumbersome. The MPM machines are ideally suited to produce prototypes and first article parts for approval or test marketing.

Low Cost tooling can be quickly produced in 2-4 weeks

Materials and injection cycles can be experimented with

Programmable parameters can be adjusted to produce suitable prototype

Single cavity tooling can easily be modified as product changes are implemented

Suitable for lab or research environments

Bridge Manufacturing

Bridge Manufacturing is the step between producing high volume finished production parts and smaller quantities that may be needed as prototypes, first articles for approval, test marketing or initial customer orders. You may need to get initial parts produced while you are waiting for a production machine to be received or available. Also, production tooling can often require considerable time to be designed and produced (16-24 weeks) delaying the time to get product to the customer or approval party.

MPM machines can fill this gap effectively to meet your Bridge Manufacturing need of plastic molded parts:

Low cost quick to produce (2-4 weeks) tooling

Easy set up for quick production

Quickly produce small batch runs for first articles of approval

Quickly produce parts for marketing and customer approval and feedback

Produce finished parts to meet customer orders while waiting for finished high production tooling

Want to speed up time to market or reduce risk involved with expensive injection molding tooling?

MPM Benchtop Plastic Injection Molding Machines Trusted by Businesses Nationwide

MPM low volume injection molding machines are ideal for bridge manufacturing, research and development, product testing, and low-volume production. A wide range of industries use our machines, including medical, automotive, consumer products, and more. With the ability to use the same plastic grade as a multi-cavity mold, engineers can test plastic blends and manufacturing optimization, marketers can test designs and colors, and your entire part or product can be optimized before full-volume production begins.

Find the Perfect Fit for Bridge Manufacturing of Your Plastic Molded Parts

MPM machines are cost effective and easy to set up and get running. The single cavity V-mold and tooling inserts can be produced quickly and economically. High quality initial or low volume production runs of finished product are easily produced by MPM injection molded machines. Our application engineering team can guide you through the machine selection process to meet your Bridge Manufacturing requirements.

Models |

||||||

|

|

|

Model 60 |

|

|

|

| Pneumatic | X | |||||

| Hydraulic | X | X | X | X | X | |

| Electric | X | |||||

| Vertical Orientation | Clamp, Inject | Clamp, Inject | Clamp, Inject | Inject | Clamp, Inject | Clamp |

| Horizontal Orientation | Clamp | Inject | ||||

| Max Shot Size (oz) | 0.5-1.50, 3.0 | 0.5-1.50 | 1.0, 2.0, 4.0 | 1.0, 2.0 | 1.0, 2.0 | 1.0, 2.0 |

| Clamping Force (Tons) | 12.0, 16.0 | 12.0 | 12.0[1][2]; 18.0[4] | 10.0 | 10.0 | 12.5 |

| Injection Pressure (PSI) | 7,068-20,480 | 7,068-20,480 | 16,065[1]; 16,593[2]; 11,398[4] | 16,000^[1]; 27,040[2] | 16,065[1]; 16,593[2] | 16,065[1]; 16,593[2] |

| Screw Displacement (cubic in) | N/A | N/A | 1.8[1]; 3.98[2]; 7.2[4] | 1.8[1]; 3.98[2] | 1.8[1]; 3.98[2] | 1.8[1]; 3.98[2] |

| Plasticizing Capacity (lb/hr) | 10 | 10.0 | 17.5[1]; 18.5[2][4] | 28.0[1]; 45.0[2] | 28.0[1]; 45.0[2] | 28.0[1]; 45.0[2] |

| Max Heat (deg F, approx) | 625 | 625 | 700[1][2]; 650[4] | 700 | 700 | 700 |

| Barrel/Cylinder Heater Wattage (W) | 1050 | 1050 | 2100[1]; 2700[2][4] | 2400[1]; 3000[2] | 2400[1]; 3000[2] | 2400[1]; 3000[2] |

| Nozzle Heater Wattage (W) | 110, 150[3] | 110 | 110 | 110 | 110 | 110 |

| Recommended Molding Area (sq in) | 6.0; 8.0[3] | 6.0 | 6.0[1][2]; 9.0[4] | 5.0 | 5.0 | 6.25 |

| Standard Mold Size (WxLxH – in) | 2.13 x 7 x 3 | 2.13 x 7 x 3 | 2.13 x 7 x 3 | 8.0 x 6.0 x 8.0 | 8.0 x 8.0 x 6.5 | 8.0 x 6.0 x 6.5 |

| Max Mold Dimensions – (WxLxH – in) | Consult Factory | Consult Factory | 6.0 x 8.5 x 5.5 | 8.0 x 8.0 DME | 8.0 x 8.0 DME | 8.0 x 8.0 DME |

| Power Req | 10A | 30A | 30A | 40A | 40A | 40A |

| 115V | 230V (1/3 Phase) | 230V (1/3 Phase) | 230V (1/3 Ph), 480V | 230V (1/3 Ph), 480V | 230V (1/3 Ph), 480V | |

| Power Comsumption (Amps) | 10.0 | 15.0 | 19.5[1]; 22.15[2][4] | 30.1 | 26.7 | 26.7 |

| Overall Dimensions – WxLxH | TBD | TBD | TBD | TBD | TBD | TBD |

| [#] denotes shot specific specs | ||||||

| # denotes shot size | ||||||

| If [#] not specified spec applies to all | ||||||

Popular Options |

||||||

| C-Frame | X | X | X | X | X | |

| Mold Heat | X | X | X | X | X | X |

| Part Ejection | X | X | X | |||

Models 55/55P/55E |

||||||

| 55 – Econmical Siemens PLC/HMI controlled reciprocating screw, bench-top injection molding machine | ||||||

| 55P – Siemens PLC/HMI controlled with recipe management, proportional pressure control and linear potentiometer tracking of screw displacement | ||||||

| 55E – Siemens based servo injection molding machine with speed based injection profiling, recipe management and quiet operation | ||||||

Model 45

Model 45 Model 50

Model 50 Model 55/55P/55E

Model 55/55P/55E Model 70

Model 70 Model 75

Model 75