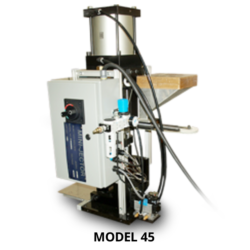

Models 45 and 50

Benchtop Molding Injection Machines

Mini-Jector models 45 and 50 are mini injection molding machines ideal for low run, prototyping, and cable overmolding applications. Both of these models are simple plunger-style machines, which restricts the type of plastic they may use, but greatly reduces their cost.

The Model 45 is a pneumatic vertical injection molding machine that can be either 110VAC or 220VAC. The Model 50 is a hydraulic vertical injection molding that utilizes 230VAC.