Overmolding cable assemblies enhances the durability, appearance, and environmental integrity of an electrical or mechanical cable assembly. The weakest part of the electrical cable assembly is the point at which the wires are attached to the electrical contacts or pins with the individual wires. Typically this connection is crimped or soldered and has limited capability to withstand pulling or flexing forces that the assembly may be subject to. By molding around the connection points with a thermo plastic the connection points are relieved of the strain that could potentially cause a failure. In addition to enhancing the mechanical integrity the molded back end between the connector and the cable can seal the cable assembly from invasive liquids that could potentially cause a short between cables or pins. The right cable overmolding machine provides the opportunity to enhance the aesthetic appearance of the cable assembly and also offers the opportunity to include product logos and part numbers.

Cable Overmolding Machines

Effective Strain Relief With Cable Overmolding

The individual soldered or crimped connections between the connector pins or electrical contacts is a potential point of failure especially if the cable is subject to accidental pulling or continuous flexing.

Cable overmolding of the back end of the connector at the junction point between the connection points and incoming multi-conductor cable provides a robust strain relief:

Eliminate mechanical failures due to incidental pulling of cable

Reduce failures in continuous flexing applications

Reduce failures of marginal electrical connections by solidifying connection point

See What Mini Injection Molding Can Do For Your Business

Get the ultimate guide to low volume plastic injection molding

Aesthetically Improve the appearance of your Cable Assembly

An overmold on the backend of your plug can be of any shape or color you desire. A sleek transition from plug to cable can make your product look rugged and fit into the design of your overall product.

Improve branding with overmold color and logo

Improve look of ruggedness and integrity

Design to fit overall product look

Part numbers or descriptions can be added

Want to speed up time to market or reduce risk involved with expensive injection molding tooling?

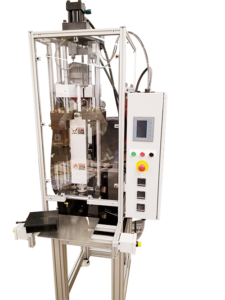

MPM Low Volume Injection Molding Machines are Trusted by Businesses Nationwide

MPM injection molding machines are ideal for cable overmolding applications. A wide range of industries use our machines, including medical, automotive, consumer products, and more. With the ability to use the same plastic grade as a multi-cavity mold, engineers can test plastic blends and manufacturing optimization, and marketers can test designs and colors.

Find the Perfect Fit

Our Application Engineering team can help you specify the proper MPM machine for your overmolding application. These injection molding machines range from portable benchtop, to floor standing, to vertical, to high precision servo controlled types that are suitable for a wide variety of applications. Medical cable assemblies, military cable assemblies, seismic field splicing or repair, electronic cable assemblies, or mechanical assemblies are all very good candidates for MPM machinery and tooling.

Models |

||||||

|

|

|

Model 60 |

|

|

|

| Pneumatic | X | |||||

| Hydraulic | X | X | X | X | X | |

| Electric | X | |||||

| Vertical Orientation | Clamp, Inject | Clamp, Inject | Clamp, Inject | Inject | Clamp, Inject | Clamp |

| Horizontal Orientation | Clamp | Inject | ||||

| Max Shot Size (oz) | 0.5-1.50, 3.0 | 0.5-1.50 | 1.0, 2.0, 4.0 | 1.0, 2.0 | 1.0, 2.0 | 1.0, 2.0 |

| Clamping Force (Tons) | 12.0, 16.0 | 12.0 | 12.0[1][2]; 18.0[4] | 10.0 | 10.0 | 12.5 |

| Injection Pressure (PSI) | 7,068-20,480 | 7,068-20,480 | 16,065[1]; 16,593[2]; 11,398[4] | 16,000^[1]; 27,040[2] | 16,065[1]; 16,593[2] | 16,065[1]; 16,593[2] |

| Screw Displacement (cubic in) | N/A | N/A | 1.8[1]; 3.98[2]; 7.2[4] | 1.8[1]; 3.98[2] | 1.8[1]; 3.98[2] | 1.8[1]; 3.98[2] |

| Plasticizing Capacity (lb/hr) | 10 | 10.0 | 17.5[1]; 18.5[2][4] | 28.0[1]; 45.0[2] | 28.0[1]; 45.0[2] | 28.0[1]; 45.0[2] |

| Max Heat (deg F, approx) | 625 | 625 | 700[1][2]; 650[4] | 700 | 700 | 700 |

| Barrel/Cylinder Heater Wattage (W) | 1050 | 1050 | 2100[1]; 2700[2][4] | 2400[1]; 3000[2] | 2400[1]; 3000[2] | 2400[1]; 3000[2] |

| Nozzle Heater Wattage (W) | 110, 150[3] | 110 | 110 | 110 | 110 | 110 |

| Recommended Molding Area (sq in) | 6.0; 8.0[3] | 6.0 | 6.0[1][2]; 9.0[4] | 5.0 | 5.0 | 6.25 |

| Standard Mold Size (WxLxH – in) | 2.13 x 7 x 3 | 2.13 x 7 x 3 | 2.13 x 7 x 3 | 8.0 x 6.0 x 8.0 | 8.0 x 8.0 x 6.5 | 8.0 x 6.0 x 6.5 |

| Max Mold Dimensions – (WxLxH – in) | Consult Factory | Consult Factory | 6.0 x 8.5 x 5.5 | 8.0 x 8.0 DME | 8.0 x 8.0 DME | 8.0 x 8.0 DME |

| Power Req | 10A | 30A | 30A | 40A | 40A | 40A |

| 115V | 230V (1/3 Phase) | 230V (1/3 Phase) | 230V (1/3 Ph), 480V | 230V (1/3 Ph), 480V | 230V (1/3 Ph), 480V | |

| Power Comsumption (Amps) | 10.0 | 15.0 | 19.5[1]; 22.15[2][4] | 30.1 | 26.7 | 26.7 |

| Overall Dimensions – WxLxH | TBD | TBD | TBD | TBD | TBD | TBD |

| [#] denotes shot specific specs | ||||||

| # denotes shot size | ||||||

| If [#] not specified spec applies to all | ||||||

Popular Options |

||||||

| C-Frame | X | X | X | X | X | |

| Mold Heat | X | X | X | X | X | X |

| Part Ejection | X | X | X | |||

Models 55/55P/55E |

||||||

| 55 – Econmical Siemens PLC/HMI controlled reciprocating screw, bench-top injection molding machine | ||||||

| 55P – Siemens PLC/HMI controlled with recipe management, proportional pressure control and linear potentiometer tracking of screw displacement | ||||||

| 55E – Siemens based servo injection molding machine with speed based injection profiling, recipe management and quiet operation | ||||||

Model 45

Model 45 Model 50

Model 50 Model 55/55P/55E

Model 55/55P/55E Model 70

Model 70 Model 75

Model 75