We provide benchtop and free standing vertical injection molding machines for low volume injection molding. Our small injection molding machines are optimized for doing cable overmolding, ASTM test specimens, low run production parts, and Seismic cable repair.

Mini Injection Molding

How Our Injection Molding Machine Works

Mini-Jector machines use mechanical advantage to generate a large clamping force (12 tons) with only a small amount of inputted effort. This force is maintained through the injection cycle.

Our benchtop models use a single hydraulic cylinder for both clamping and carriage duties, which reduces the cost of manufacture.

Based on these and other innovative design elements, the Mini-Jector can produce injection molded parts at a significantly lower cost than larger machines.

Applications for Small Injection Molding Machines

See What Mini Injection Molding Can Do For Your Business

Get the ultimate guide to low volume plastic injection molding

Industries We Serve

Turning Innovation Into Value

The Mini-Jector small injection molding machine has a rich, diverse history, dating back to 1946. Because of the small footprint and low cost, many companies have found the Mini-Jector ideal for product development and short run production. Over the years, many improvements have been made to the Mini-Jector models, and with the product line acquisition in 2017, Electro-Matic Ventures has continued to make improvements to these machines.

Electro-Matic Integrated, Inc., a business unit of Electro-Matic Ventures, is an ISO : 9001, Employee owned company. We’re committed to turning innovation into value in everything we do.

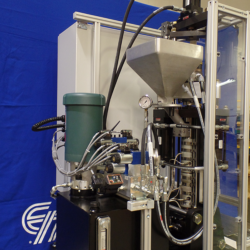

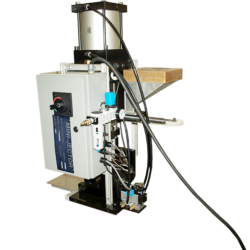

Our Small Injection Molding Machines

Models 45/50

- Pneumatic or hydraulic options

- Plunger style machines

- Low cost

- Benchtop application

Models 55/55/55E

- Benchtop Reciprocating Screw Designs

- Hydraulic or electric options

- Production Quality Parts

Models 70/75

- Hydraulic operation

- Horizontal injection molding

- Uses vertical clamp force