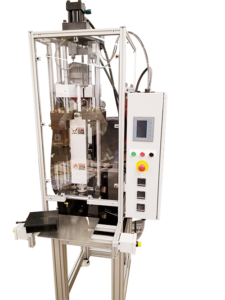

The Electro-Matic Vertical Injection Molding machine is a popular choice for Engineering Schools, Technical Schools, Vocational Schools, and Product Development Laboratories. Because of the small footprint and low cost of this injection molding it is a practical choice for schools offering polymer, plastics, or mechatronics curriculum. The vertical injection molding machine can be either pneumatic, hydraulic,or a complete electrical servo powered machine to be able to teach the basic principles of power conversion and control of various transmission media. See here for the various machine designs. The molding machine can also be either open loop, proportional valve control, or electrical servo control. It also can utilize PID feedback loops thus allowing for Proportional, Integral, and Derivative control curriculums in a real world practical setting. Utilizing state of the art Siemens PLC’s, Operator Interfaces, and Servo Motor Drives on these injection molding machines allows for students to learn programming and configuration of the most widely used controls system (Siemens) in the world

University/Tech School Labs

Learn About the Benefits and Applications of Mini Injection Molding

Get the ultimate guide to low volume plastic injection molding

Injection Molding for Educational Labs

The machine can use additive printed tooling to be compatible with additive manufacturing curriculum in the real world application of plastic injection molding. As the tooling can also use relatively low cost machined aluminum tooling with a unique V-mold design in addition to digitally printed tooling it can be used for a wide variety of Research and Development projects for internal education or to serve Industries that may be clients of your Research Department.

Industry prototype development is also very suitable for the Electro-Matic Vertical or Benchtop injection molding machine due to its ease of set up, small footprint, and low cost tooling. The low volume injection molded nature of this machine can efficiently produce several hundred prototypes of first articles for product testing and market acceptance in a wide variety of industry applications.

Mechatronics is a fast growing field of study in the engineering curriculum at Universities and Technical Schools. Electro-Matic and Siemens offer digital twinning technology for injection molding machines. Here is a link of the digital twin of our Model 55E reciprocating screw injection molding machine.

MPM Injection Molding Machines Are Trusted by the University and Tech School Labs Nationwide

Want to speed up time to market or reduce risk involved with expensive injection molding tooling?

Find the Perfect Fit

At MPM, we make it easy to find the best plastic molding machine for your educational lab needs. We provide three different benchtop models, as well as standing models for higher production runs, so you can find the right fit. Choose from pneumatic or hydraulic power, screw displacement or plunger operation, and varying degrees of clamp force. If you aren’t sure which machine is ideal for your needs, we can help. Contact us for more information about any injection molding machine.

Mini-Jector Model #45

- Requires only 115 or 220 VAC 1 Phase supply

- One (1) high capacity heating cylinder

- Plunger assembly choice of bore sizes

- 0.50 ounce to 1.5 ounce “shot” size

- Non-drool nozzle

- Straight orifice nozzle (0.125” diameter) also available

Mini-Jector Model #50

- One (1) high capacity heating cylinder

- Plunger assembly choice of bore sizes: 0.50 ounce to 1.5 ounce “shot” size

230 VAC single or three phase power supply options - Sliding ring shut off tip with “non-drool” shut-off nozzle

- Straight orifice nozzle (0.125” diameter) also available

Mini-Jector Model #55

- Aluminum material hopper with dump tube and shut off

- Automatic self compensating feed system

- HMI with diagnostic capability

- Control system programmed for manual or semi-automatic operation

- All moving parts covered by safety shroud