Mini-Jector machines use mechanical advantage to generate a large clamping force (12 tons) with only a small amount of inputted effort. This force is maintained through the injection cycle. Our benchtop models use a single hydraulic cylinder for both clamping and carriage duties, which reduces the cost of manufacture. Based on these and other innovative design elements, the Mini-Jector can produce injection molded parts at a significantly lower cost than larger machines.

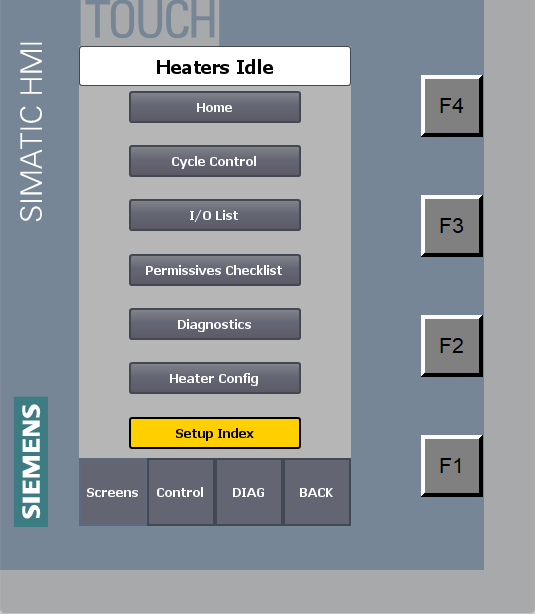

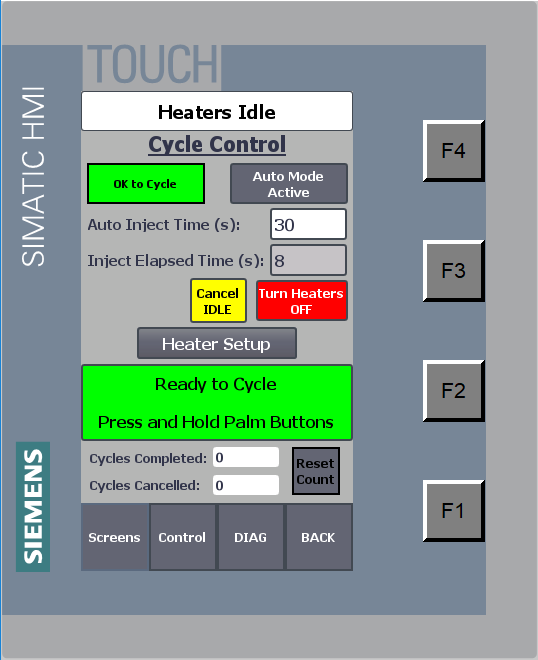

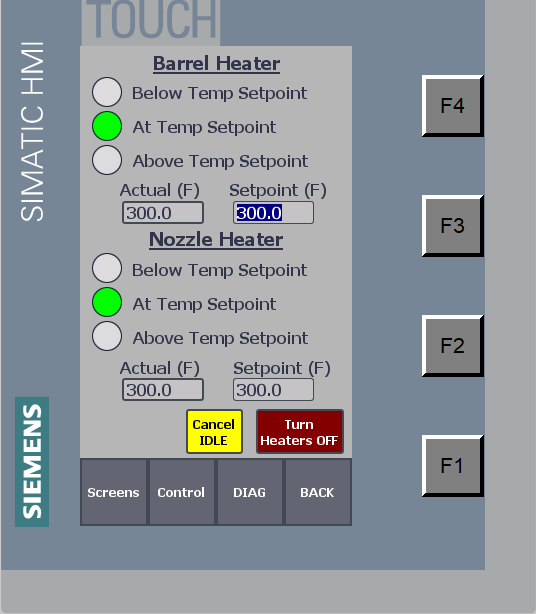

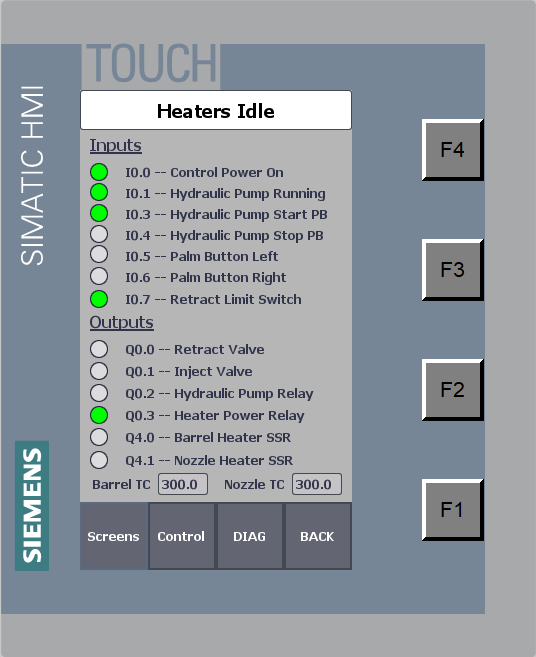

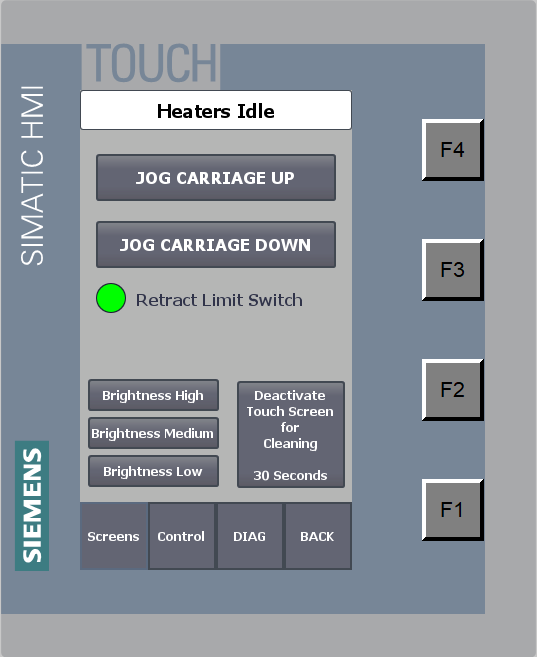

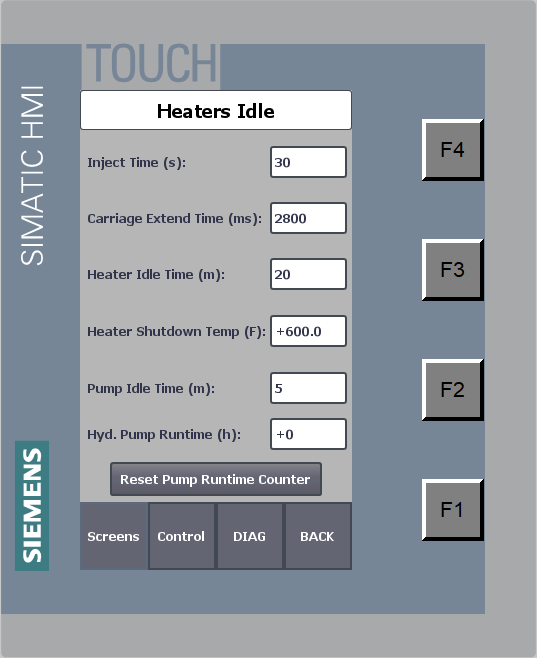

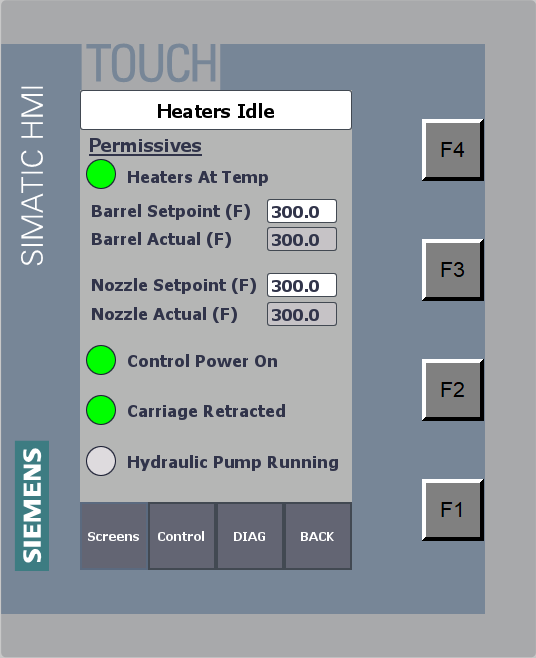

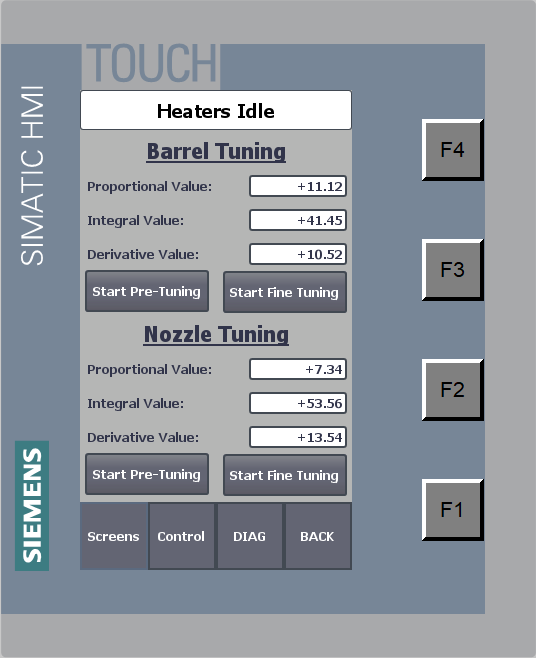

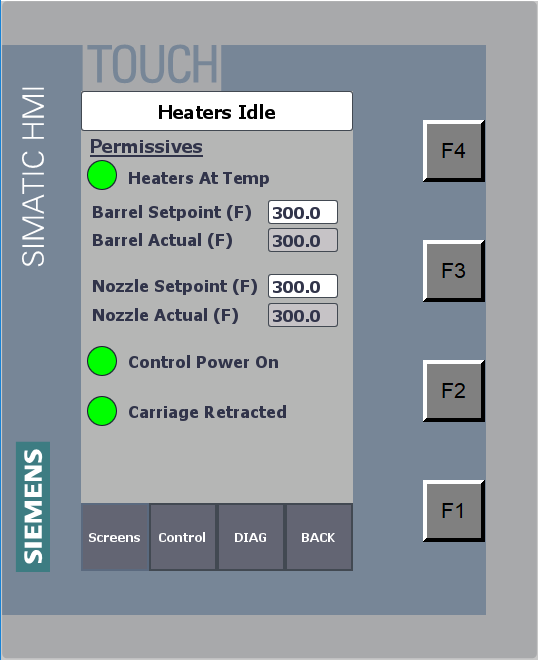

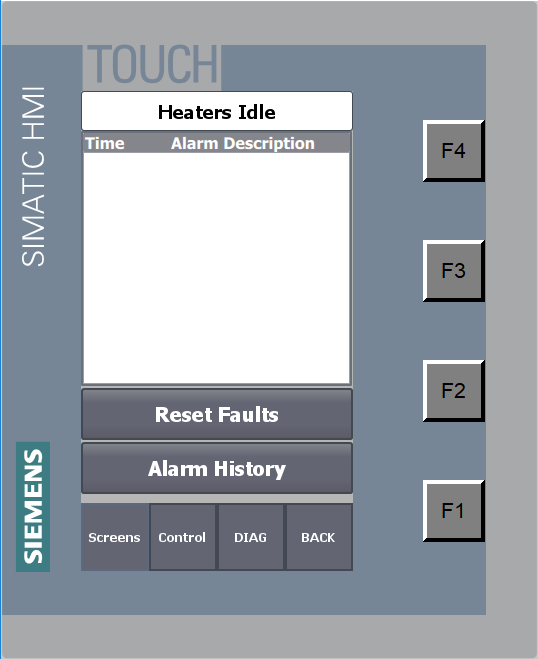

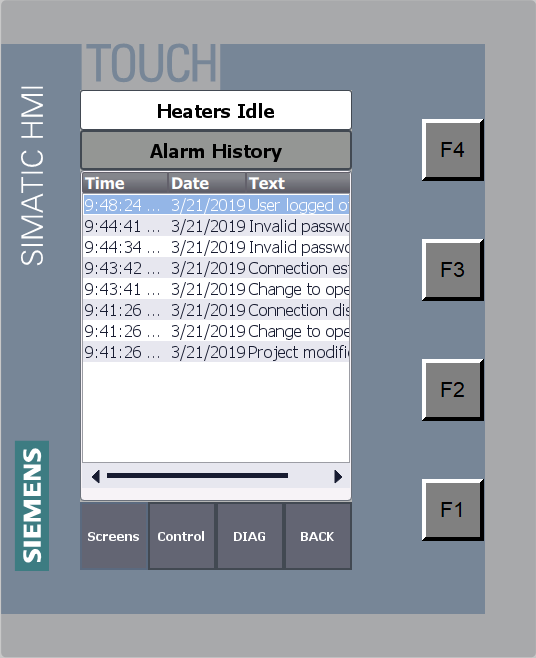

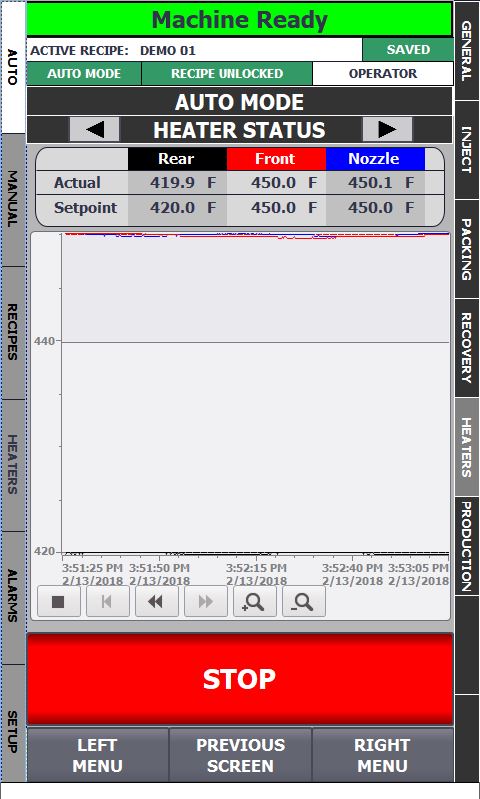

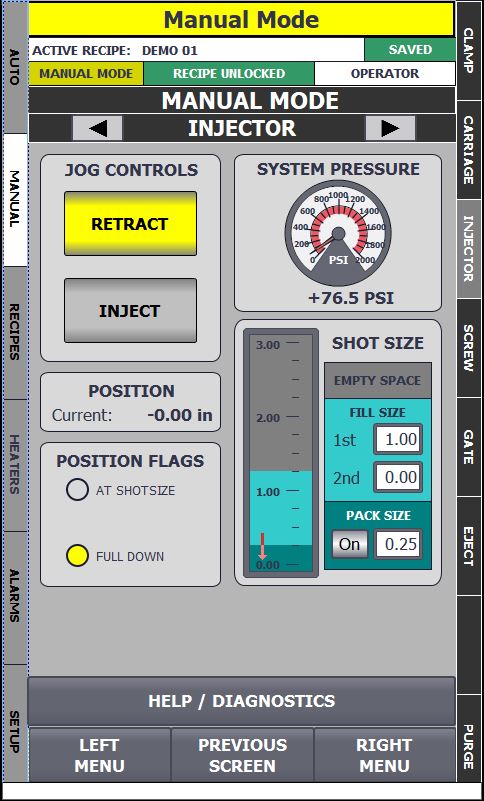

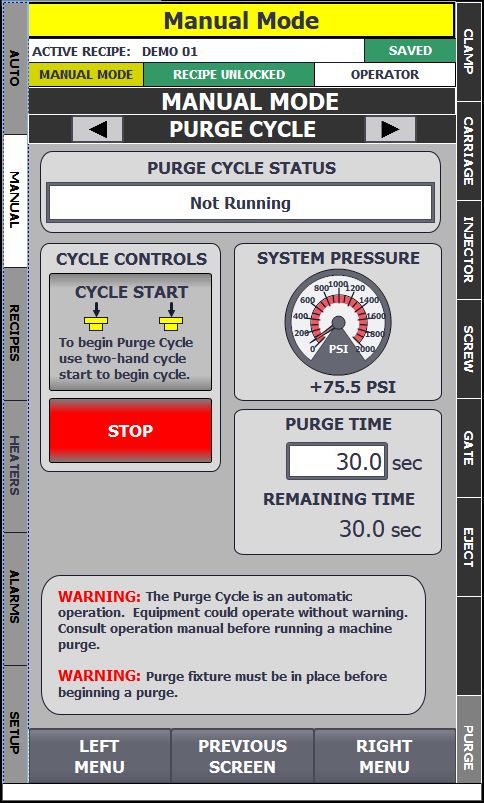

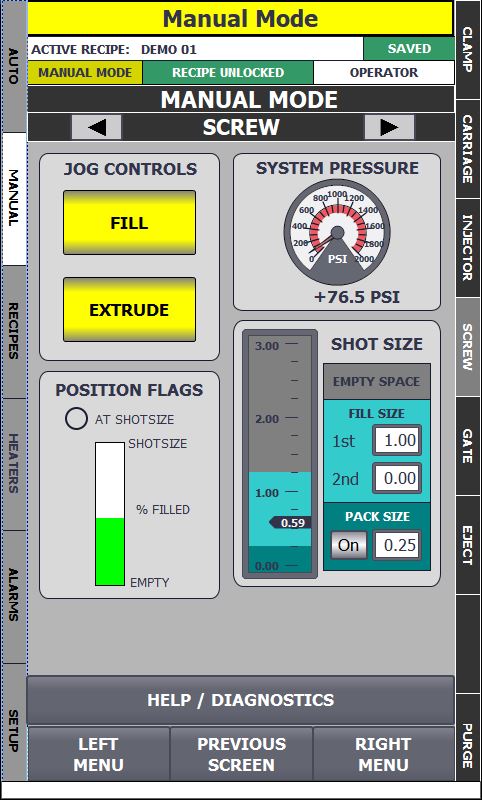

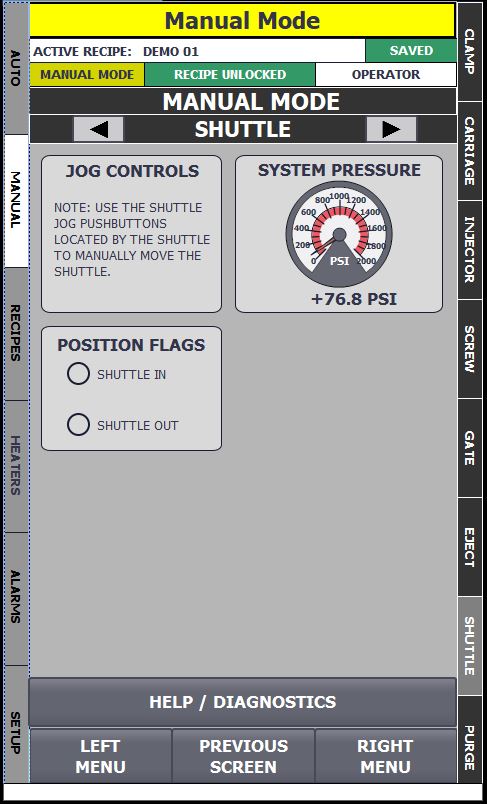

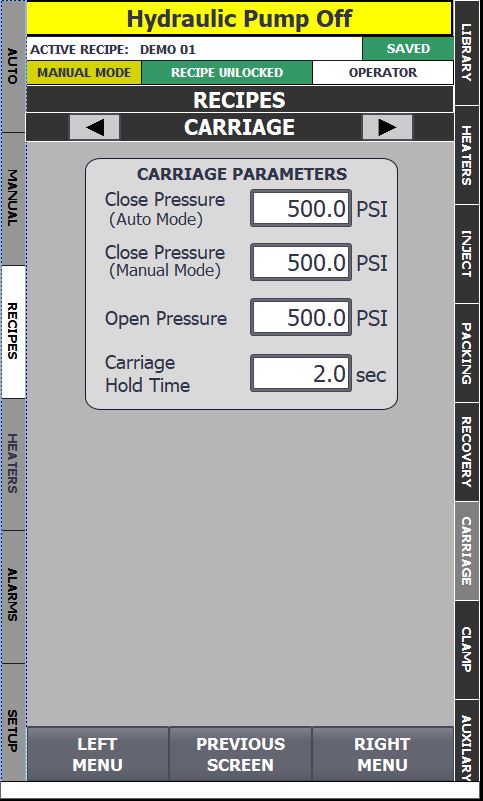

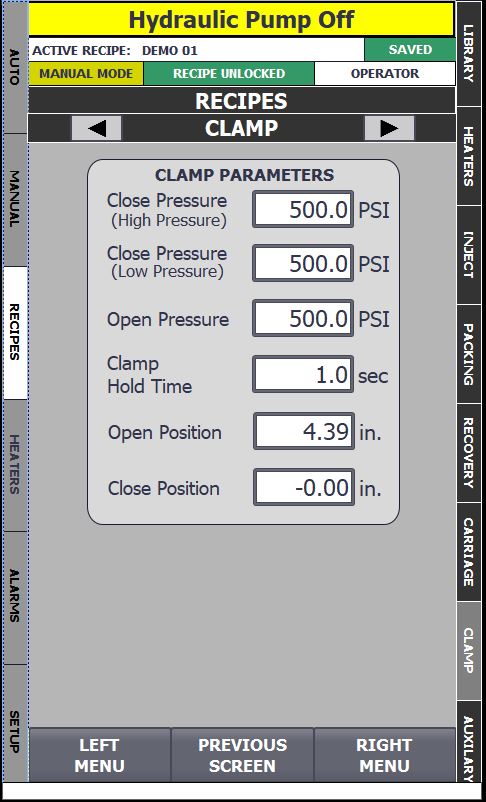

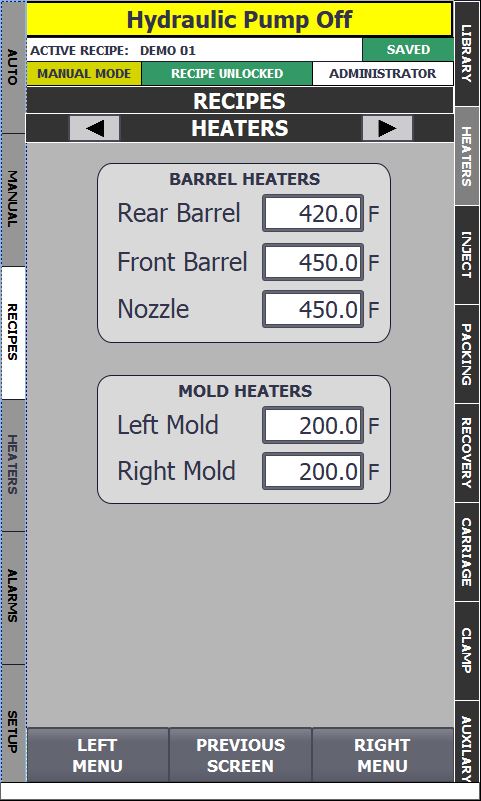

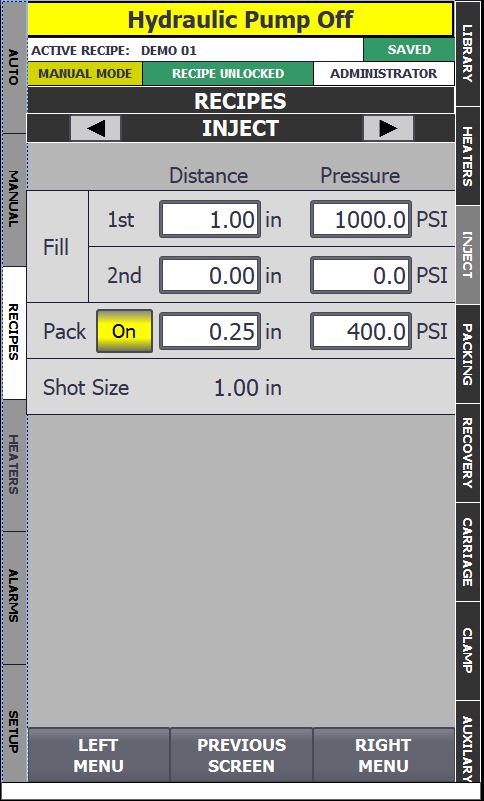

Below you will find screenshots, photos, and videos to help you better understand how our machines work.