As new products are conceived, designed, and produced it is almost always necessary to produce prototypes and first articles for functional product testing, color selection, customer acceptance, and product marketing evaluation. Low Volume Injection Molding can be a key component to the Product Development of Plastic Injected Molded products as you can produce prototypes and first articles very quickly and relatively inexpensively. This is primarily due to the low cost and simplicity of both the machine design and tooling utilized in an Electro-Matic Vertical Injection Molding machine. High volume injection molding machines are not usually practical for producing prototypes as they require production level multi-cavity tooling which is expensive and can take dozens of weeks to produce. These concepts are discussed in depth in the e-book “The Ultimate Guide to Low Volume Injection Molding”

Product Development and Prototyping

See What Mini Injection Molding Can Do For Your Business

Get the ultimate guide to low volume plastic injection molding

Injection Molding for Product Development and Prototyping

As products are developed and plastic materials are evaluated for use in these products it is important to test that these plastic products have the proper tensile strength, impact resistance, water absorption, and flexural properties. The most common way to do this is to produce dog bone or ASTM test specimens that can be evaluated to ASTM D3641 standards by a properly equipped testing laboratory. “The Standard Practice for Injection Molding Test Specimens of Thermoplastic Molding and Extrusion Materials” can be reviewed here.

The Electro-Matic benchtop injection molding machine is very suitable for producing ASTM D3641 test specimens for evaluation. This low cost injection molding machine is very simple to set up and run. The reciprocating screw design, high injection forces, and high heat capabilities allow machine owners to process a diverse range of thermoplastic polymers into ASTM test specimens. The recipe functionality of these machines allows for process parameters to be stored for each system so that switching back and forth between different materials can be done in a very efficient manner. Low cost injection V mold tooling that is a feature of Electro-Matic vertical injection molding machine allows for producing a variety of plastic dog bone test specimens at a relatively low cost.

MPM Injection Molding Machines Are Trusted for Prototyping and Product Development Nationwide

Want to speed up time to market or reduce risk involved with expensive injection molding tooling?

Find the Perfect Fit

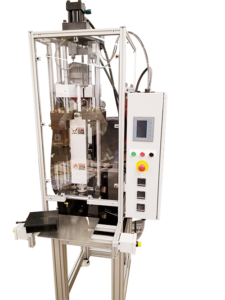

At MPM, we make it easy to find the plastic injection molding machine for your prototyping and product development needs. We provide three different models, as well as standing models for higher production runs, so you can find the right fit. Choose from pneumatic or hydraulic power, screw displacement or plunger operation, and varying degrees of clamp force. If you aren’t sure which machine is ideal for your needs, we can help. Contact us for more information about any injection molding machine.

Mini-Jector Model #45

- Requires only 115 or 220 VAC 1 Phase supply

- One (1) high capacity heating cylinder

- Plunger assembly choice of bore sizes

- 0.50 ounce to 1.5 ounce “shot” size

- Non-drool nozzle

- Straight orifice nozzle (0.125” diameter) also available

Mini-Jector Model #50

- One (1) high capacity heating cylinder

- Plunger assembly choice of bore sizes: 0.50 ounce to 1.5 ounce “shot” size

230 VAC single or three phase power supply options - Sliding ring shut off tip with “non-drool” shut-off nozzle

- Straight orifice nozzle (0.125” diameter) also available

Mini-Jector Model #55

- Aluminum material hopper with dump tube and shut off

- Automatic self compensating feed system

- HMI with diagnostic capability

- Control system programmed for manual or semi-automatic operation

- All moving parts covered by safety shroud